Choosing the pump system for your business can significantly impact operational efficiency and cost-effectiveness. Whether you are in manufacturing, construction, water management, or any other industry requiring fluid transfer, understanding your specific needs is crucial.

A well-matched pump system contributes to seamless operations and reduces maintenance and replacement costs. This article provides an overview of various pump types, their applications, and tips for selecting the best option based on your business requirements.

Understanding Various Pump Types

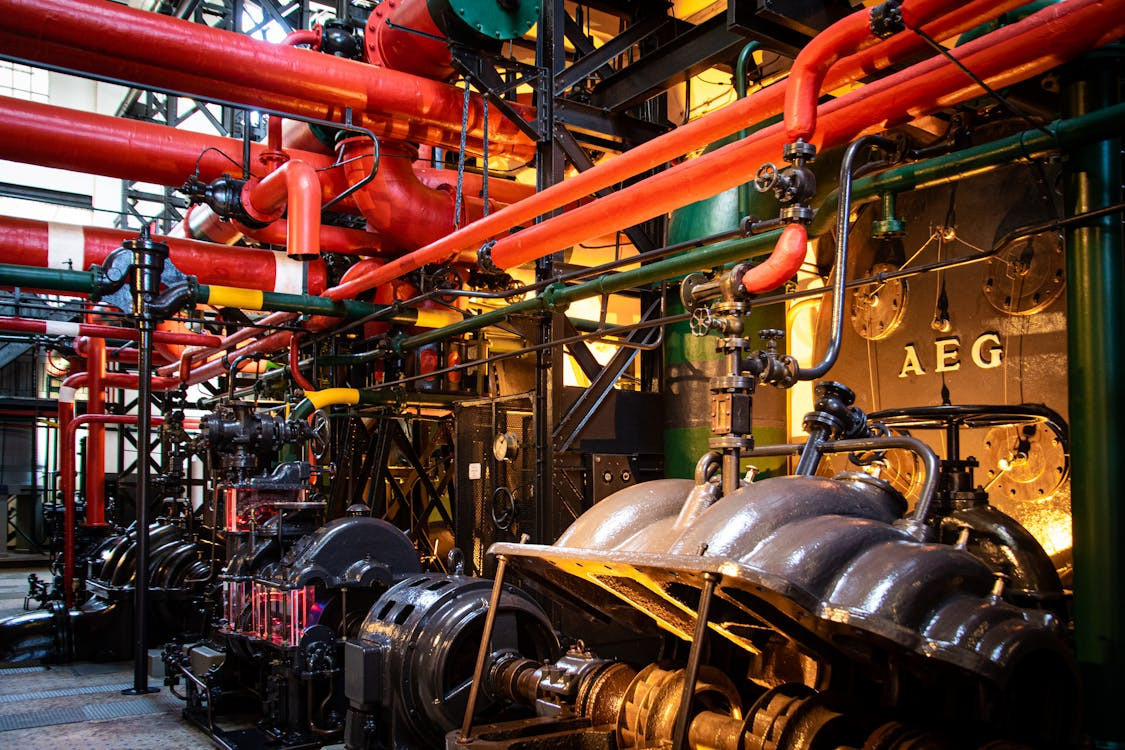

The world of pumps is expansive, with each type designed for specific applications and characteristics. Some of the common categories include positive displacement pumps and centrifugal pumps. Positive displacement pumps move fluid by trapping a fixed amount and forcing it through the discharge. They are particularly suited for viscous fluids and provide a consistent flow. Common types include gear, diaphragm, and screw pumps.

Centrifugal pumps use rotational energy, converting it into hydrodynamic energy. These pumps excel at transferring low-viscosity fluids like water or thin oils and find extensive use in municipal water supply systems, chemical processing, and HVAC systems.

Understanding these distinctions is fundamental to selecting the pump that aligns with your operational requirements. When choosing the right pump, make sure to compare different types, from sewage pumps to sump pumps. Pumps designed for moving sewage manage solid waste, while sump pumps primarily handle groundwater and prevent flooding in basements or low-lying areas. Deciding between these options requires assessing the fluid’s characteristics, environmental conditions, and disposal requirements.

Key Factors in Pump Selection

Selecting a pump system is not just about matching the type of pump to the task. Several essential factors must influence your decision-making process. First, consider the fluid being moved. Its viscosity, temperature, and corrosive properties will affect the pump’s efficiency and longevity. For instance, using a standard centrifugal pump for highly viscous fluids can lead to underperformance and operational issues.

Next, evaluate the required flow rate and pressure. These specifications will guide you in selecting a pump that meets your operational demands without excess energy consumption. Low flow rates paired with high pressure may lead to cavitation, damaging the pump over time. Conducting a thorough analysis of these parameters can help avert future failures and improvements in overall efficiency.

Consider the physical limitations of your location. Space restrictions might necessitate selecting a compact design without sacrificing functionality. For some applications, a submersible pump may be a better choice, while for others, a surface-mounted option will suffice. Each scenario demands careful consideration of location, accessibility, and maintenance needs.

Energy Efficiency and Operating Costs

Energy consumption remains a significant portion of operational costs for many businesses. As such, choosing an energy-efficient pump can yield substantial savings over its lifespan. Evaluating the pump’s efficiency rating, typically denoted in beta or horsepower per gallon per minute (GPM), will inform decisions on long-term cost implications.

Assess the materials used in the pump’s construction. Corrosion-resistant materials such as stainless steel typically prolong the pump’s lifespan and reduce the need for replacements. Not only does this save funds for repairs, but it minimizes downtime.

Factor in the lifecycle costs associated with maintenance, as less frequent servicing translates to continued productivity. Integrating smart technology within pump systems can facilitate monitoring energy usage and operational efficacy in real-time. Automated systems can alert operators to irregularities, enhancing prompt interventions and minimizing unplanned downtime.

Reviewing the Maintenance Requirements

No pump system remains maintenance-free. Establishing a strong maintenance regime is essential for preventing breakdowns and prolonging the operational lifespan of your equipment. Some pumps require routine inspections and lubrication, while others may have more stringent maintenance protocols due to complex designs.

Knowing the maintenance demands of the pump type you choose helps ensure compliance and minimizes unexpected disruptions. Negotiating maintenance contracts with suppliers can provide support while offering access to expert assistance when faced with challenges.

A solid maintenance plan may include regularly scheduled training for operators. Ensuring staff are well-informed about pump operation can lead to fewer mistakes, reducing the risks of costly mishaps caused by incorrect usage.

Involving Specialists in Your Decision-Making

Collaborating with pump specialists or consultants can be an effective way to navigate the complexities of pump selection. Expertise in fluid dynamics, pump technology, and operational requirements allows these professionals to provide valuable insights and tailored recommendations.

They can assist in assessing your business’s unique conditions and matching your needs to the appropriate pump systems. Assessment often involves visiting your site for a deeper understanding of environmental conditions and operational workflows. Input from experienced professionals can highlight potential pitfalls and areas where optimization can significantly impact productivity.

Engaging a consultant can lead to long-term relationships where ongoing support and advice keep your pump systems running efficiently as your operations evolve. This partnership ensures your investment in pump technology remains robust and relevant to changing demands.

Choosing the right system is not merely a matter of picking an option from a catalog. It requires a deep understanding of your specific needs, combined with a thorough evaluation of available options and associated costs. Careful consideration of the type of fluid, application demands, energy efficiency, and maintenance requirements will lead to a well-informed decision that enhances productivity and reduces costs.