The manufacturing industry is undergoing a seismic shift, driven by integrating advanced technologies that enhance efficiency, precision, and adaptability. At the heart of this transformation lies the concept of smart manufacturing, where automation, data analytics, and robotics converge to redefine production processes. Among the many innovations shaping this landscape, collaborative robots, or cobots, play a pivotal role in streamlining operations and fostering innovation.

The Rise of Smart Manufacturing

Smart manufacturing represents a paradigm shift from traditional production methods to interconnected, data-driven systems. This evolution is characterized by adopting cyber-physical systems, where machines, sensors, and software work harmoniously to optimize workflows and decision-making.

From Isolated Systems to Integrated Networks

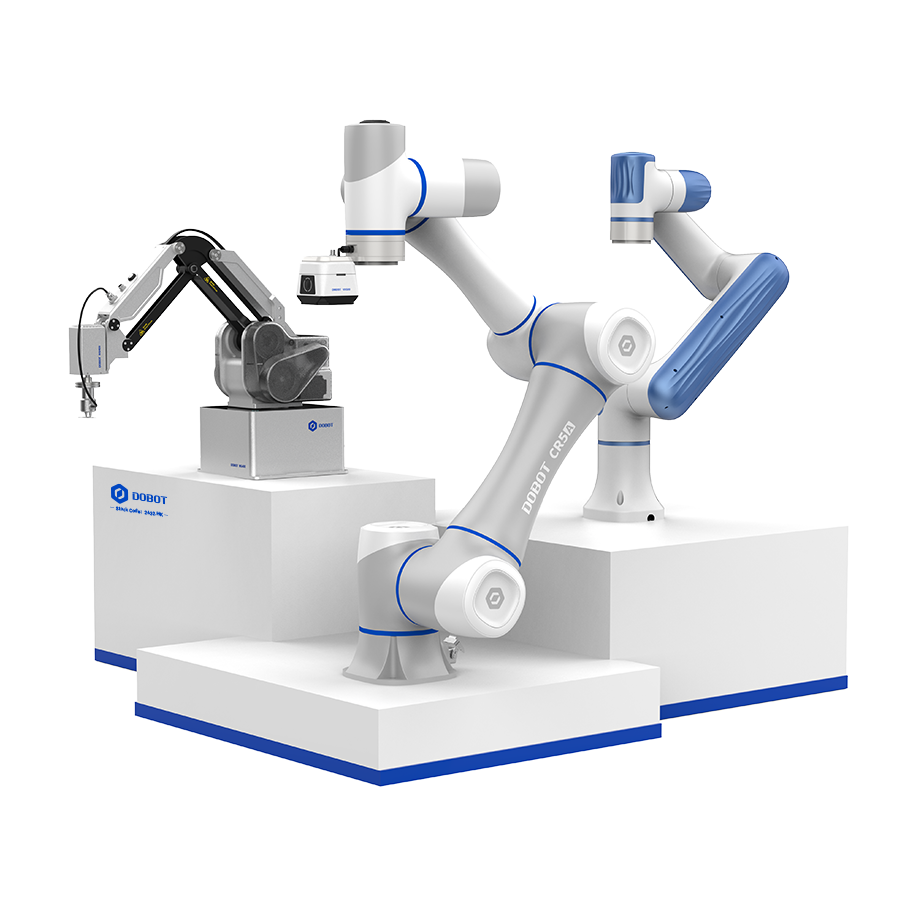

In the past, manufacturing relied on isolated systems with limited communication between different stages of production. Today, integrating IoT devices and real-time data analytics has enabled seamless connectivity across the entire production line. Collaborative robots, such as the DOBOT robots, are designed to integrate effortlessly into these networks, enhancing responsiveness and efficiency.

Sensors embedded in machinery provide valuable insights into performance, enabling predictive maintenance and reducing downtime. This interconnected approach improves productivity and ensures higher quality control by offering visibility into every stage of the manufacturing process.

The Role of Collaborative Robotics

Collaborative robots have emerged as a cornerstone of smart manufacturing. Unlike traditional industrial robots, which often operate in isolation, cobots are designed to work alongside human operators. This collaboration enhances flexibility and allows manufacturers to adapt easily to changing demands.

Cobots excel in tasks that require precision and repetition, such as assembly, inspection, and material handling. Taking on physically demanding or monotonous tasks reduces the strain on human workers and improves workplace safety. Advanced safety features, like pre-collision detection systems, ensure that cobots can operate in shared spaces without harming their human counterparts.

Key Benefits of Collaborative Robots in Manufacturing

The adoption of collaborative robots offers a multitude of benefits that extend beyond mere automation. These robots are transforming industries by enabling smarter, more efficient production processes.

Enhanced Precision and Accuracy

Collaborative robots are engineered to deliver exceptional precision, making them ideal for meticulous attention-to-detail tasks. The DOBOT robot, with a precision range of ±0.2 mm, ensures consistent quality in applications such as electronics assembly and quality inspection.

Flexibility and Scalability

One of the standout features of cobots is their adaptability. They can be easily programmed to perform various tasks, from screw-driving and polishing to sorting and palletizing. This versatility allows manufacturers to scale their operations without requiring extensive reconfiguration.

Improved Safety Standards

Safety is a top priority in modern manufacturing environments. Collaborative robots are equipped with advanced safety technologies, such as contactless pre-collision systems, that enable them to detect obstacles and adjust their movements accordingly. This ensures a safe and productive workspace for both robots and human operators.

Real-Time Data Integration

Integrating collaborative robots with IoT and manufacturing execution systems (MES) enables real-time data analysis and decision-making. This connectivity allows manufacturers to monitor production metrics continuously, identify bottlenecks, and implement improvements on the fly.

Applications of Collaborative Robots in Industry 4.0

Collaborative robots are driving the adoption of Industry 4.0 by automating complex tasks and enhancing operational efficiency. Their applications span various industries, including automotive, electronics, and logistics.

Assembly and Material Handling

Collaborative robots excel at tasks such as component placement, screw-driving, and polishing in assembly lines. Their precision and repeatability ensure consistent quality, while their compact design allows them to operate in confined spaces.

Quality Inspection

Vision-guided systems integrated into collaborative robots enable automated quality inspection. These systems use AI-powered defect detection to identify issues in real-time, reducing the reliance on manual inspection and improving overall product quality.

End-of-Line Palletizing

Collaborative robots streamline palletizing processes by automating the sorting and stacking of products. This reduces manual labor and increases the speed and accuracy of palletizing operations.

Overcoming Challenges in Implementation

While the benefits of collaborative robots are undeniable, their successful implementation requires careful planning and consideration.

Matching Robots to Tasks

It is crucial to select the right robot for a specific application. Payload capacity, precision, and repeatability must meet the task’s requirements. For example, lightweight robots are ideal for delicate electronics assembly, while heavier models are better suited for automotive applications.

Ensuring Safety and Compliance

Safety is a critical aspect of human-robot collaboration. Manufacturers must conduct thorough risk assessments and implement safety measures, such as pre-collision detection systems, to minimize hazards. Compliance with industry standards, such as ISO 10218-1, ensures that collaborative robots meet the highest safety benchmarks.

Training and Workforce Integration

Integrating collaborative robots into the workforce requires proper training and education. By equipping employees with the skills needed to operate and maintain these robots, manufacturers can foster a culture of innovation and adaptability.

The Future of Smart Manufacturing

As the manufacturing industry continues to evolve, the role of collaborative robots will only grow significantly. Their ability to enhance precision, improve safety, and adapt to changing demands makes them indispensable in the era of Industry 4.0.

The DOBOT robot is a prime example of how collaborative robotics can revolutionize smart manufacturing. Its advanced features and ability to integrate seamlessly into modern production environments highlight the transformative impact of automation. By adopting such technologies, manufacturers can achieve greater efficiency, foster innovation, and build a more sustainable future.

Conclusion

Collaborative robots are transforming the manufacturing landscape, delivering exceptional precision, adaptability, and safety. By incorporating technologies such as IoT and AI, these robots enable industries to adopt smarter, more efficient production methods. From improving quality control to automating repetitive tasks and meeting dynamic demands, these advancements highlight the potential of robotics in driving the future of Industry 4.0. Embracing these innovations ensures manufacturers remain competitive, forward-thinking, and ready to tackle the challenges of the evolving industrial world.